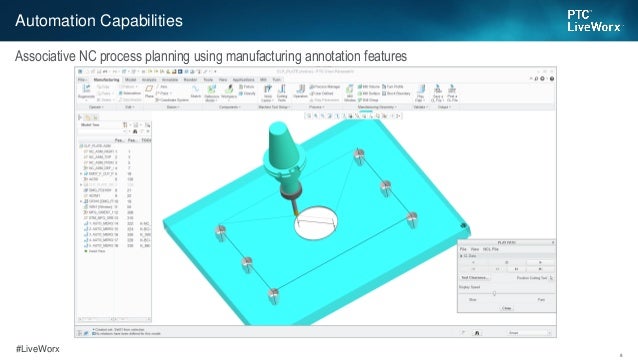

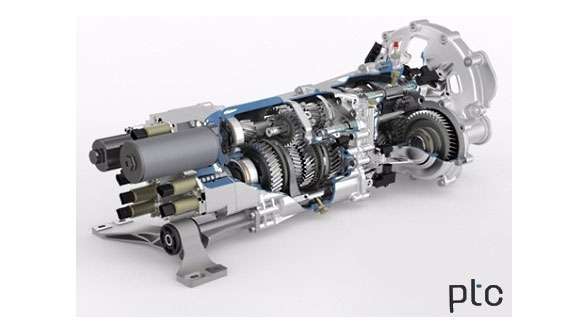

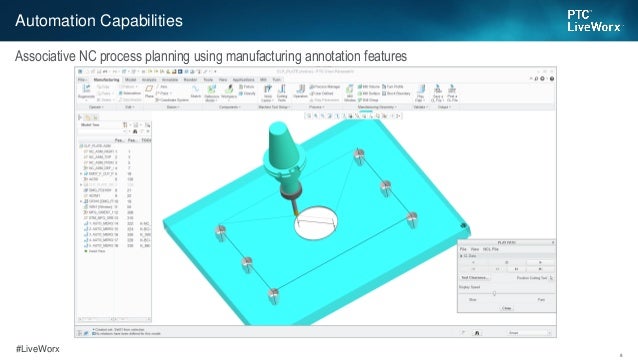

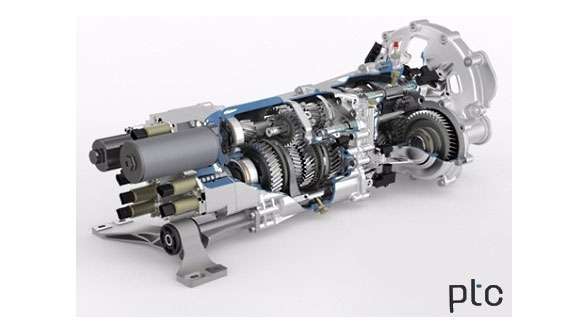

Model-Based Definition (MBD) and Detailing Improvements: Continued investment in model-based product design, especially in surface finishing and welds, means that users can include specialized downstream manufacturing information right on the model. PTC’s generative design technology also adds capabilities to define optimization studies with designed-in safety factors and natural frequency limits. More Powerful Simulation and Generative Design Capabilities: Advanced multiphysics from Ansys have been integrated into the Creo simulation portfolio.  Usability and Productivity: Investments across the core modeling environment focus on usability and productivity, including updates to the model tree to make it faster to structure, document and understand design intent, and a new function for dividing surfaces to improve analysis and product definition. asm.PTC launched the ninth version of its Creo computer-aided design (CAD) software. Creo 9 helps engineers deliver product designs in less time and encourages innovation with emerging technologies such as generative design, real-time simulation, and additive manufacturing, the company reports. As for manufacturing, the app has tooling options for molding, die-casting and progressive tooling design. Creo has numerous analysis tools which help with the development of the product which include human factors, manufacturing tolerance, mould flow and design optimization. Product design processes include the ability to generate geometry of other integrated design disciplines such as industrial and standard pipe work and complete wiring definitions. The capabilities of the product can be split into three main groups, that is Engineering design, Analysis and Manufacturing. Companies with family-based or platform-driven product strategy make use of this approach for what they need to perform successful design processes is a prescriptive design strategy. The application is based on the parametric modeling approach, which means that it uses parameters, dimensions, features, and relationships to enable design automation and optimization of design and product development processes.

Usability and Productivity: Investments across the core modeling environment focus on usability and productivity, including updates to the model tree to make it faster to structure, document and understand design intent, and a new function for dividing surfaces to improve analysis and product definition. asm.PTC launched the ninth version of its Creo computer-aided design (CAD) software. Creo 9 helps engineers deliver product designs in less time and encourages innovation with emerging technologies such as generative design, real-time simulation, and additive manufacturing, the company reports. As for manufacturing, the app has tooling options for molding, die-casting and progressive tooling design. Creo has numerous analysis tools which help with the development of the product which include human factors, manufacturing tolerance, mould flow and design optimization. Product design processes include the ability to generate geometry of other integrated design disciplines such as industrial and standard pipe work and complete wiring definitions. The capabilities of the product can be split into three main groups, that is Engineering design, Analysis and Manufacturing. Companies with family-based or platform-driven product strategy make use of this approach for what they need to perform successful design processes is a prescriptive design strategy. The application is based on the parametric modeling approach, which means that it uses parameters, dimensions, features, and relationships to enable design automation and optimization of design and product development processes.

Its users are mostly mechanical engineers, designers and manufacturers. It provides solid modeling, assembly modeling, 2D orthographic views, FEA, direct and parametric modeling, sub-divisional and NURBS surface modeling, and tools for mechanical designers. PTC Creo by Parametric Technology Corporation, known as Pro/Engineer is a 3D CAD, CAM, CAE, and associative solid modeling application.

0 kommentar(er)

0 kommentar(er)